how to clean the nozzle

The world of 3d printing, especially for those who deal with it at a hobby level, is unfortunately not free from problems. An unexpected event that can happen is that related to the obstruction of the nozzle of our hotend on the part of the filament. Fortunately, it does not happen often and in any case there are many ways to clean it, for example it is often sufficient to extrude a material with a higher operating temperature than the one causing the cork, or if the block was due to the abs, a bath of a few hours in acetone often solves the problem. In my specific case, the block was due to some plaque that I had neglected, causing it not only to deteriorate but also to dust. This caused, after a few minutes of printing, an obstruction of the nozzle which was not easy to remove with the most common methods. So I came up with a “soooo homemade” way to clean the nozzle.

Attention, this procedure must be performed with due precautions and by adults, it is not without risks and I do not take any responsibility for damage to things and / or people.

It must be performed in a very ventilated environment and with the availability of an extinguishing agent at hand. The best thing would be to clean the nozzle outdoors using a gas soldering iron such as this one used in construction. not having this possibility, I used the flame coming from a burner in the kitchen. Let’s see what we need:

not having this possibility, I used the flame coming from a burner in the kitchen. Let’s see what we need:

common iron wire

a vise

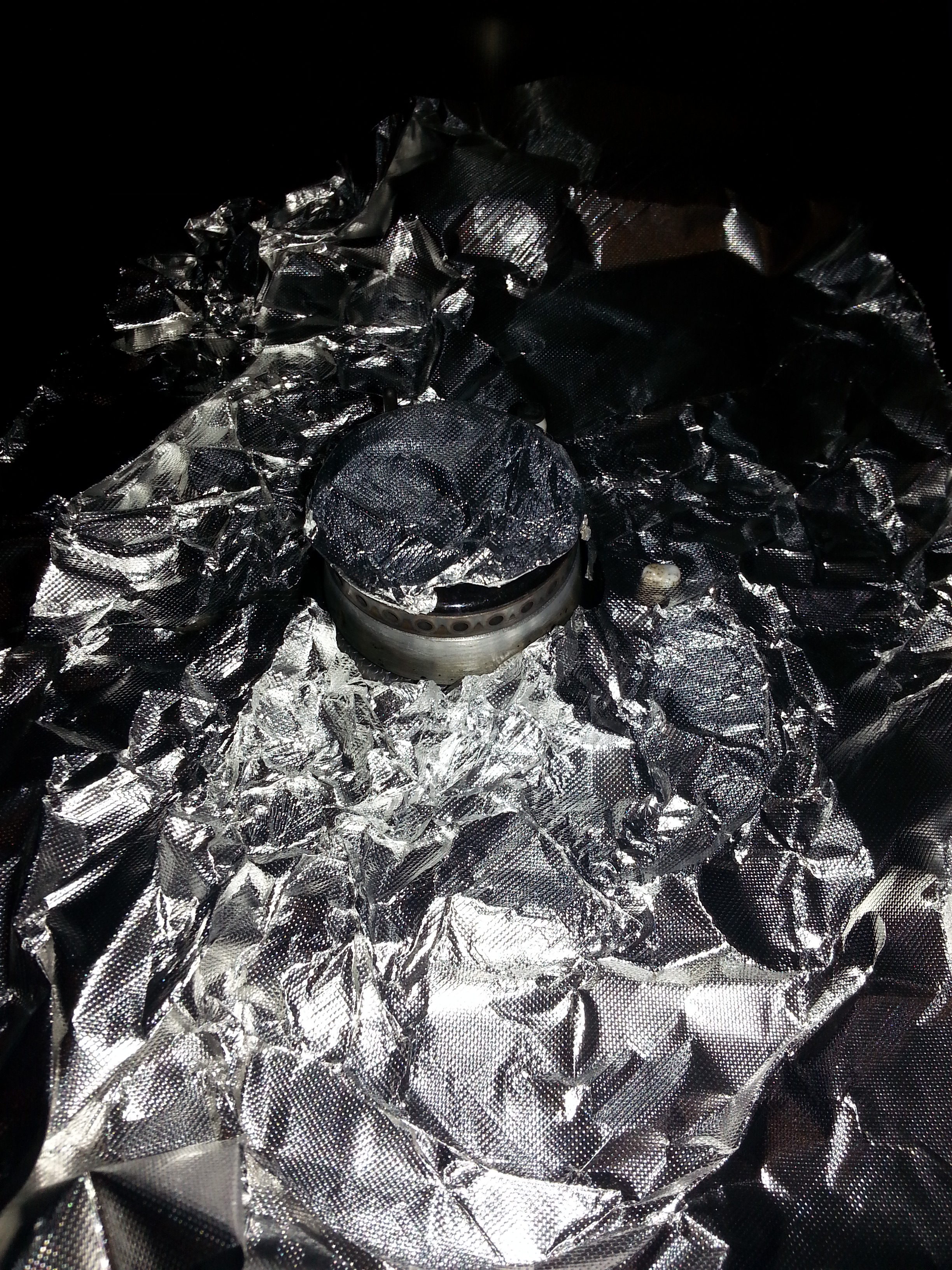

aluminum foil to protect the kitchen

we tie the nozzle with the iron wire

we tighten the opposite end in the vice in order to better adjust the positioning of the nozzle on the flame

when the flame was lit a few minutes from the nozzle the pla that obstructed it began to pour

falling on the aluminum sheet placed before

I waited for all the material to come out and taking the nozzle with pliers (attention, hot) I gently tapped on a marble threshold on the side of the filament entrance

even if the photo does not show it, some deposits of encrustations have come out completely freeing the nozzle.

Attention, the validity of this procedure varies according to the material from which we have to clean the nozzle, for example by carrying out the same procedure to clean a nozzle clogged with PETG I obtained this result

definitely not desirable in a home environment. For this reason I repeat the advice to carry out the operation in an external environment and using the flame produced by a gas welder as a flame. I renew the call for caution for everyone given the use of open flames and highly flammable materials.

if you want to know more, if you need help write to info@3deasy.it

if you want to be updated on the next article, fill in the following fields to subscribe to the newsletter.